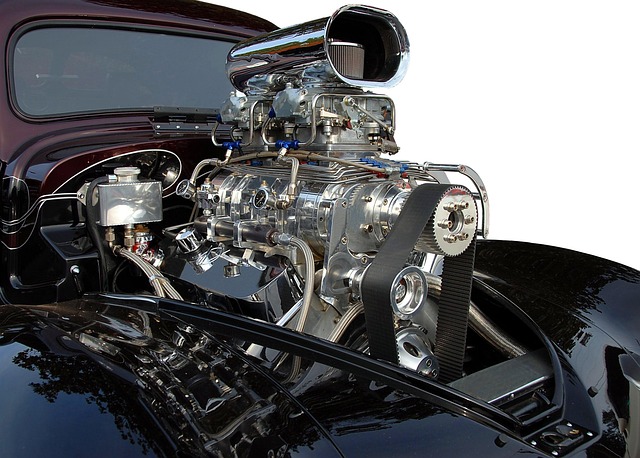

TIG welding auto body is a revolutionary technique offering precise and versatile bonding for enhanced structural integrity in collision repair. Skilled technicians use tungsten and inert gas to execute intricate welds in tight spaces while preserving vehicle aesthetics, making it ideal for Mercedes Benz collision repair or car dent removal. This method welds various metals, ensuring strong, clean joints with minimal distortion, suitable for hail damage repair, car paint restoration, and high-quality auto repairs.

“TIG welding auto body repair and restoration has emerged as a game-changer in the automotive industry. This article delves into the profound advantages of employing TIG (Tungsten Inert Gas) welding for auto body work, setting it apart from conventional methods. By exploring its precision, versatility, and superior quality outcomes, we uncover why TIG welding is a powerful tool for professionals. Get ready to discover how this technique enhances durability, ensures quality assurance, and redefines the standards of auto body craftsmanship.”

- TIG Welding: A Powerful Auto Body Tool

- Advantages Over Traditional Methods

- Enhancing Durability and Quality Assurance

TIG Welding: A Powerful Auto Body Tool

TIG welding auto body has emerged as a powerful tool in the realm of collision repair shops and car bodywork. This precise and versatile technique is not just limited to metal fabrication; it plays a pivotal role in car restoration, enabling skilled technicians to create strong, durable bonds that enhance structural integrity. Unlike traditional welding methods, TIG (Tungsten Inert Gas) welding offers unparalleled control, allowing for intricate and fine-tuned welds, even in the tightest of spaces.

The advantages of TIG welding auto body are numerous. It produces clean, consistent results with minimal heat input, preserving the integrity and original aesthetics of the car bodywork. Moreover, its ability to weld a wide range of metals makes it an indispensable asset for any professional involved in car restoration, ensuring that each repair is executed with both precision and efficiency.

Advantages Over Traditional Methods

TIG welding auto body offers numerous advantages over traditional methods used in automotive collision repair. One of its key benefits is precision and control. This type of welding allows for intricate, complex designs and precise adjustments, making it ideal for detailed work often required in Mercedes Benz collision repair or car dent removal processes. The highly focused heat source ensures minimal heat input into the surrounding material, preserving the integrity and original shape of the components.

Another advantage is the ability to weld a wide variety of materials, from steel to aluminum, without issue. This versatility makes it a preferred choice in modern automotive manufacturing and repair, where mixed metal compositions are common. Moreover, TIG welding produces strong, clean joints with minimal distortion, leading to longer-lasting repairs and superior structural integrity.

Enhancing Durability and Quality Assurance

TIG welding auto body is a process that significantly enhances durability and quality assurance. This advanced technique, which stands for Metal Inert Gas welding, offers precise control over heat input, allowing for clean and strong welds. By carefully managing the heat, TIG welding minimizes the risk of structural weaknesses or internal stress that can compromise the integrity of auto body repairs. The result is a superior finish with enhanced structural stability, making it ideal for both aesthetic restoration and structural reinforcement.

In the context of hail damage repair or car paint repair, TIG welding auto body provides a reliable solution. It ensures that not only are the visible imperfections corrected but also the underlying structural components restored to their optimal condition. This meticulous approach is equally valuable in high-quality auto repair services, where maintaining the vehicle’s original integrity and value is paramount. By adopting TIG welding, auto body shops can offer customers durable repairs that stand the test of time, surpassing expectations in terms of both functionality and aesthetics.

TIG welding auto body has emerged as a superior method, offering numerous advantages over conventional techniques. Its precision and versatility make it an invaluable tool for achieving exceptional durability and quality in automotive repairs and restorations. By understanding and leveraging the benefits of TIG welding, professionals can enhance the overall strength, aesthetics, and longevity of vehicle bodies, ensuring customer satisfaction and maintaining high industry standards.