TIG welding auto body (Gas Metal Arc Welding, GMAW) is a specialized technique crucial for collision repairs, offering precision and minimal heat input to preserve structural integrity and aesthetics. This method, favored for intricate joins and high-quality results, streamlines processes in modern auto body shops. With its versatility and accuracy, TIG welding leads innovation in auto body work, enabling faster repair times, reduced waste, and superior quality, particularly beneficial for paintless dent repair.

TIG welding auto body has emerged as a pivotal technique in collision repairs, offering precision and strength. This article delves into the intricate world of TIG welding, exploring its fundamental process and how it enhances auto body repair quality. We’ll uncover the advantages, from improved structural integrity to time and cost savings. Furthermore, we’ll discuss its versatility and potential future applications, making it a game-changer in the automotive industry’s pursuit of efficient, high-quality repairs.

- Understanding TIG Welding: A Fundamental Process in Auto Body Repair

- Advantages of TIG Welding for Collision Repairs and Its Impact on Quality

- The Future of Auto Body Work: Exploring the Efficiency and Versatility of TIG Welding Techniques

Understanding TIG Welding: A Fundamental Process in Auto Body Repair

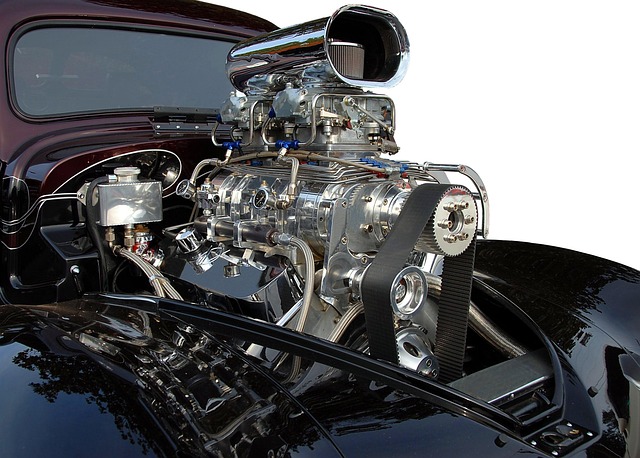

TIG welding auto body is a specialized technique that plays a fundamental role in collision repairs. It stands for Gas Metal Arc Welding (GMAW), and it’s a process where a continuous metal wire is used to join two pieces of metal. This method introduces minimal heat into the workpiece, preserving the integrity and structural strength of automotive components. By focusing on precision and control, TIG welding allows for intricate joins, making it ideal for complex auto body repairs.

In an auto collision center, understanding this process is crucial for achieving high-quality results in tire services and subsequent auto painting stages. Skilled technicians use TIG welding to seamlessly mend damaged panels, ensuring a robust and aesthetically pleasing finish. This technique’s versatility and precision make it a cornerstone of modern auto body repair practices.

Advantages of TIG Welding for Collision Repairs and Its Impact on Quality

TIG welding auto body has emerged as a game-changer in collision repairs, offering several advantages over traditional welding methods. Its precision and control allow for minimal heat input, which is crucial for preserving the integrity of vehicle paint repair and surrounding materials. This technique ensures that only the necessary areas are heated, reducing the risk of damage to the collision center’s work and the overall automotive body shop process.

The impact on quality is profound. TIG welding provides strong, clean, and aesthetically pleasing welds, enhancing the structural integrity of the vehicle. It allows for intricate and detailed work, which is particularly important in modern car designs. This level of precision not only improves the appearance of the repair but also ensures the safety and reliability of the collision center’s work, making it a preferred method in the industry for top-quality auto body repairs.

The Future of Auto Body Work: Exploring the Efficiency and Versatility of TIG Welding Techniques

The future of auto body work is looking increasingly innovative, and TIG welding auto body is at the forefront of this transformation. This highly precise and versatile technique promises to revolutionize collision repairs by offering both enhanced efficiency and superior quality. By seamlessly fusing metal components together, TIG welding can create robust bonds that rival, if not surpass, the strength of the original factory-fitted parts.

One of the standout benefits is its application in paintless dent repair, where the technique’s subtlety allows for the restoration of damaged panels without compromising the car’s aesthetics. This precision also translates to faster repair times and reduced material waste, making it an attractive solution for both automotive repair shops and car paint services seeking to streamline their operations while maintaining high standards.

TIG welding auto body has emerged as a game-changer in collision repairs, offering unparalleled precision and quality. By understanding the fundamental process and its advantages, auto body shops can enhance their efficiency and produce superior results. As technology advances, the versatility of TIG welding techniques promises to revolutionize auto body work, ensuring durable and aesthetically pleasing repairs for years to come.