TIG welding auto body repairs has revolutionized the industry with precise, non-consumptive arc technique, resulting in clean and strong welds. Offers greater heat input control, minimizing metal distortion and damage. Enhances efficiency in collision centers, enabling faster turnaround times without sacrificing quality. Versatile for diverse metal types and vehicle parts, ideal for modern auto body repair practices, transforming repairs with stronger bonds and quicker times compared to traditional methods.

TIG welding auto body has emerged as a game-changer in the automotive repair industry, revolutionizing how vehicle damage is addressed. This precise and efficient technique offers significant advantages over traditional methods, notably faster repair times without compromising structural integrity. By understanding TIG welding’s fundamentals, auto body shops can implement strategies to streamline workflows, resulting in stronger bonds and quicker turnaround times. Discover how this modern approach enhances efficiency and customer satisfaction in the competitive automotive market.

- Understanding TIG Welding for Auto Body Repairs

- Advantages: Faster Repair Times and Stronger Bonds

- Techniques to Enhance Efficiency in Auto Body Shops

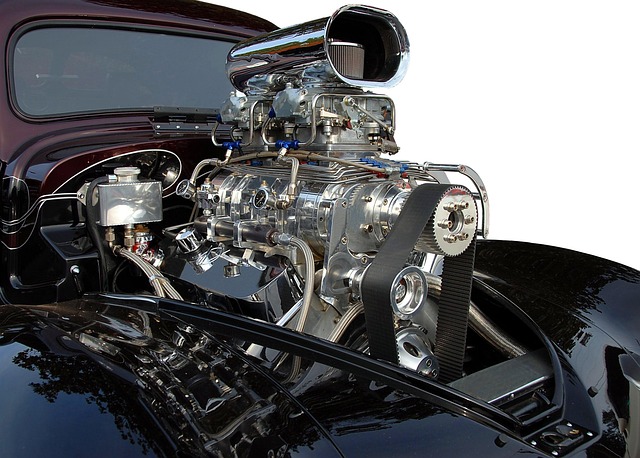

Understanding TIG Welding for Auto Body Repairs

TIG welding auto body repairs have emerged as a game-changer in the automotive industry. This precision technique involves using a non-consumptive arc to join metal components, ensuring clean and strong welds. Unlike traditional methods, TIG welding allows for greater control over heat input, resulting in less metal distortion and reduced risk of damage during the repair process.

In an auto collision center, where time is of the essence, understanding TIG welding can significantly enhance vehicle collision repair efficiency. By utilizing this advanced method, technicians can achieve faster turnaround times without compromising quality. Moreover, TIG welding minimizes the need for extensive grinding and finishing, streamlining tire services and overall repair procedures. Its versatility makes it suitable for a wide range of metal types, making it an ideal solution for various vehicle parts, from panels to frames.

Advantages: Faster Repair Times and Stronger Bonds

TIG welding auto body has revolutionized the way vehicle repairs are conducted, offering significant advantages over traditional methods. One of its key benefits is the substantial reduction in repair times. This advanced welding technique allows skilled technicians to precisely fuse metal components together with exceptional speed and accuracy. By utilizing a high-intensity arc and specialized gases, TIG welding minimizes heat input, enabling faster cooling rates without compromising structural integrity.

Moreover, TIG welding fosters stronger bonds between auto body parts. Unlike other welding methods that might create internal stress points, TIG provides a clean and consistent fusion, resulting in superior joint strength. This advantage is particularly notable in car dent removal processes, where precise and swift repairs are essential to maintain the vehicle’s structural integrity and aesthetic appeal. As such, TIG welding has become an indispensable tool for top-notch car repair shops, ensuring efficient vehicle repair and restoring damaged cars to their original condition faster than ever before.

Techniques to Enhance Efficiency in Auto Body Shops

In the fast-paced world of auto body repair, efficiency is key to keeping up with demand and reducing costs. Techniques such as TIG welding auto body have revolutionized collision centers and car body restoration processes. This specialized process allows for precise and consistent welds, enabling faster turnaround times. By training technicians in TIG welding methods, shops can streamline their workflows and enhance overall productivity.

Additionally, efficient bumper repair practices further contribute to the speed enhancement. With TIG welding auto body, repairs are not just about fixing damage; they involve intricate artistry that ensures structural integrity and aesthetic appeal. This meticulous approach not only expedites the repair process but also results in high-quality car body restoration, setting new standards for excellence in the industry.

TIG welding auto body has emerged as a game-changer in the automotive repair industry, offering both faster repair times and stronger bonds. By understanding this technique and implementing efficient shop practices, auto body shops can significantly enhance their productivity. The benefits of TIG welding extend beyond just speed; it ensures durable repairs that meet or exceed original equipment standards. As the demand for swift yet high-quality auto body work continues to grow, TIG welding is poised to remain a vital tool in modern repair practices.