TIG welding auto body is a specialized, precise technique using a non-consumable tungsten electrode to create strong, clean welds with exceptional heat control, ideal for accident repairs, scratch repair, collision damage, and custom fabrication. This method maintains structural integrity and original aesthetics, revolutionizing auto body repair and restoration, outperforming traditional methods like arc welding.

In today’s automotive industry, precision is key, especially for vehicle repair and restoration. Among various welding techniques, TIG (Tungsten Inert Gas) welding auto body stands out for its meticulousness. This article explores why TIG welding has become indispensable for achieving unparalleled accuracy in auto body work. By understanding the fundamentals of TIG welding and its advantages over traditional methods, you’ll appreciate its role as a game-changer in precision repairs and restorations.

- Understanding TIG Welding for Auto Body Work

- Precision Benefits in Vehicle Repair and Restoration

- Advantages Over Traditional Welding Techniques

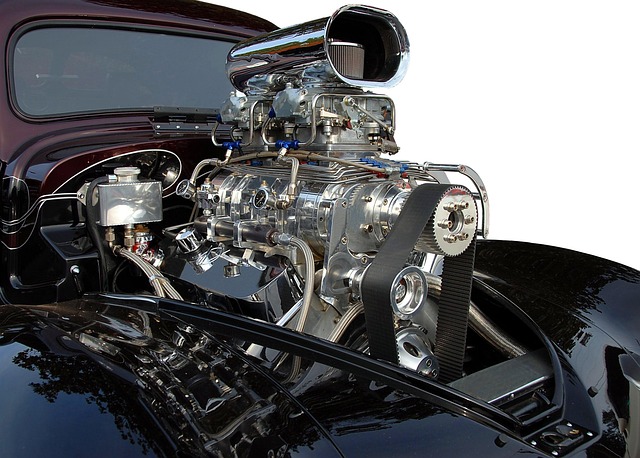

Understanding TIG Welding for Auto Body Work

TIG welding auto body is a specialized technique that has become an indispensable tool for precision repairs and customization in the automotive industry. This process involves using a non-consumable tungsten electrode to join metal components, creating strong and clean welds. Unlike traditional arc welding methods, TIG welding offers exceptional control over heat input, allowing technicians to precisely manage the melting point of the metals being joined. This level of precision is critical for auto body work, where achieving seamless, structural integrity is paramount.

Whether it’s for repairs after an accident (including scratch repair and collision damage repair) or for custom fabrication, TIG welding provides a range of benefits. It minimizes heat impact on surrounding materials, preserving the original structure and aesthetics of the vehicle. The technique also allows for intricate designs and complex geometries, enabling professionals to deliver high-quality vehicle repair services that meet even the most demanding aesthetic standards.

Precision Benefits in Vehicle Repair and Restoration

In the realm of vehicle repair and restoration, achieving precision is paramount to ensuring both structural integrity and aesthetic excellence in auto body work. TIG welding auto body stands out as a game-changer in this domain. This advanced technique allows for unparalleled accuracy in joining metal components, resulting in seamless welds that are nearly indistinguishable from the original vehicle parts. In a car repair shop or collision center, precision is not just about visual appeal; it’s critical for maintaining the structural strength of vehicles, ensuring they meet safety standards, and preserving their value.

When restoration specialists employ TIG welding auto body, they can meticulously rebuild and reinforce damaged vehicle bodywork. This level of detail translates into longer-lasting repairs and restores the car to its pre-accident condition or even enhances its original appearance. For collision centers aiming to provide top-tier services, adopting TIG welding practices is essential for delivering precision that meets modern expectations in vehicle repair, ultimately fostering customer satisfaction.

Advantages Over Traditional Welding Techniques

TIG welding auto body has emerged as a game-changer in the automotive industry, offering numerous advantages over traditional welding techniques. This precision method involves using a non-consumable electrode to produce a strong, clean weld, resulting in superior quality and strength. In contrast, methods like arc welding can lead to porosity and poor joint integrity, which are common issues in vehicle repair processes.

One of the key benefits of TIG welding is its versatility. It allows for intricate and detailed work, making it ideal for auto collision centers where precise repairs are crucial. Moreover, TIG welding generates less heat input, reducing the risk of metal distortion or burn-through, a common problem in car repair shops. This technique also enables faster cooling, minimizing the chance of thermal shock, which can compromise the structural integrity of the vehicle body.

TIG welding auto body has emerged as a game-changer in vehicle repair and restoration, offering unparalleled precision and superior strength. By understanding its unique capabilities and advantages over traditional methods, professionals can ensure top-notch quality and longevity in every project. The benefits of TIG welding are clear: it’s the future of precise auto body work, revolutionizing how we restore and maintain our vehicles.